The Automatic plastic HDPE open head 120L 200L drum blow molding machine is used to make abs car hollow products , A wide variety of materials can be used for the machine, which are suitable for producing 10-30L PE bottle. Extrusion system using a hard gear reducer and inverter. The die head system adopts central-incoming extrusion die made of special steel, imported hydraulic valve and seal parts with proportional control valve. The control system consists of PLC and Human-machine interface imported from Japan, an automatic temperature control module and imported electrical parts.

Blow molding machine parameter

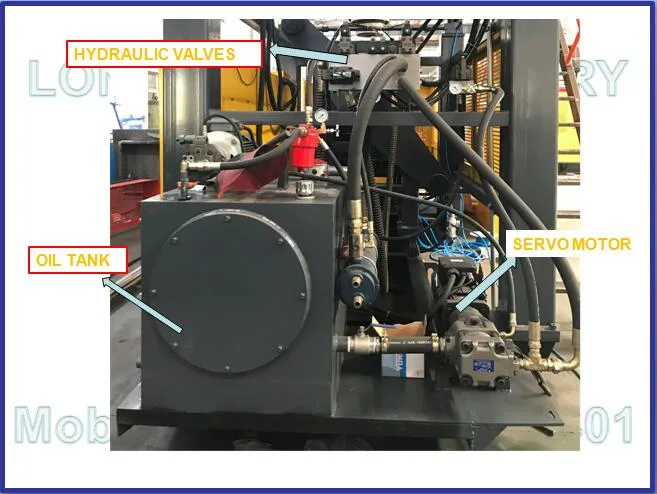

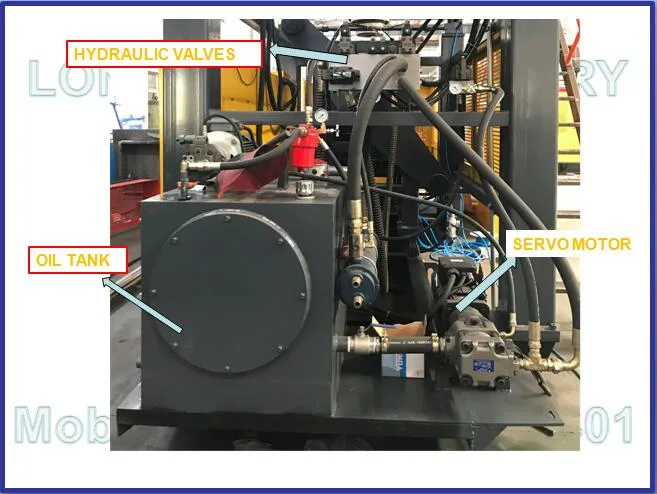

Blow molding machine photo

Welcome you contact us for more machine details.

Blow molding machine parameter

| Item | Code item | Parameter | Note |

| Extruder (Main extruder ) | Max capacity | 120L | |

| Main screw | Ø100mm | High-efficiency mixing | |

| Screw L/D | 25-30 | ||

| Screw material | 38CrMoALA | ||

| Max.Extruder consumption | 180-250KG/hr | ||

| Twisting transition method | Electrical machinery,Gearbox,AC motor | Hard gear surface decelerator with AC regulator | |

| Driving motor | 55KW | ||

| Screw rotate speed | 5-60r/min | ||

| Ahead /back adjusting | Yes | ||

| Up/ down adjusting | Yes | ||

| Temperature control zone | 5 | ||

| Heating power | 22kw | ||

| Cooling for blower | 5 | ||

| Cooling function | Yes | Cooling water | |

| Clamping unit (Mold opening/closing unit) | Structure | With three bar timing clamping structure in high speed and high force,to achieve quality products | |

| Clamping directions | Linear guide | For high precise location for longer service life | |

| Platen dimension | 1100*1100mm | (W*H) | |

| Max.mold dimension | 900*1400mm | (W*H) | |

| Platen distance | 600-1400mm | Min.-Max. | |

| Clamping force | 360-560KN | ||

| Mold thickness stroke | 610-750mm | ||

| Fixing pattern of the mold | Mold press platen | ||

| Mold open/close stroke control | Inducing Switch +moving | Discriminate mold opening/closing end, mold opening/closing slow speed | |

| Light Electric Safety protect | Taiwan | ||

| Die head | Form | Accumulator | First in, First out |

| Material | 38CrMoALA,inner mirror treatment | ||

| Accumulator volume | 18L | ||

| Output of injecting | 13kg | HDPE,5502 | |

| Max die-pin diameter | 450-510mm | ||

| Heating Method | Stainless steel heating ring, precision +1% | ||

| Temperature control zone | 5 | ||

| Blow-air | Yes | ||

| Adjusting of parison thickness | Yes | MOOG 100 point | |

| Adjusting method of thickness | Inner mold adjusting+5mm |

Blow molding machine photo

Welcome you contact us for more machine details.